OLKLIN®-BD

Biodispersant

INTRODUCTION:

OLKLIN-BD is a superior liquid product developed as a bio-dispersant for cooling water applications. The product improves the performance of water systems where fouling by microbiological slimes is reducing overall system efficiency, by removing and dispersing the unwanted deposits. OLKLIN-BD is also extremely effective at controlling oil based fouling. OLKLIN-BD is effective in both re-circulating and once-through cooling water systems.

CONTENTS OF THE OLKLIN-BD:

The product comprises a powerful surface active agents and polymers along with suitable biocides. It is biodegradable in nature.

| Property | OLKLIN-BD |

|---|---|

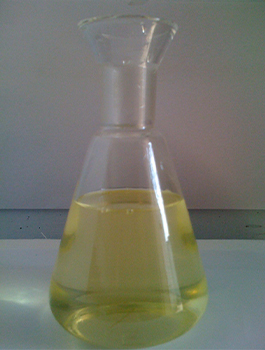

| State | Liquid |

| pH | 5.0-8.0 |

| Density | 1.00±0.03 |

| Color | Water white to pale yellow |

| Odor | Almost Odorless |

| Solubility in water | Soluble in all proportions |

WE CAN PRODUCE THE PRODUCT AS PER YOUR REQUIRED SPECIFICATIONS.

BENEFITS OF USING OLKLIN-BD:

- Effective in both re-circulating and once-through cooling water systems.

- Designed to penetrate and disperse accumulated biomasses.

- Assists water treatment biocides to penetrate biological slime, thereby enhancing their effectiveness.

- Effective for the removal of oil and grease from cooling towers.

- Control bio-films and microbiologically influence corrosion (MIC).

- Improves heat transfer capacity of the pipes.

- Prevents chalking of the pipes and thereby increases circulation capacity to its full level.

- Decreases frequent shutdowns, periodical cleaning and servicing of the cooling systems.

- Increases profitability by reducing extra energy, manpower, expenses and forcefully untimely-allotted time.

DIRECTION FOR USE:

OLKLIN-BD should be fed continuously or slug dosed into the system at a point where it will be mixed and uniformly distributed. OLKLIN-BD is essentially non-corrosive and dosing equipment may be of mild steel, stainless steel, teflon, polyethylene, acrylic resin or polypropylene. Dosage levels will be in the range of 1100ppm depending on the fouling tendency. Higher dosages may be required if the system is heavily fouled. Feed OLKLIN-BD several hours prior to treating the system with oxidizing biocide for maximum effectiveness. For further technical assistance please contact MCS.

STORAGE:

Store in Cool & Dry place away from direct sunlight.

PACKING:

35 kg / 50 kg / 200 kg HDPE carboys and drums.