PHOSPHOMAN®-235

Diethylene Triamine Penta (Methylene Phosphonic) Acid – DTPMPA

DIETHYLENE TRIAMINE PENTA (METHYLENEPHOSPHONIC) ACID

Introduction: PHOSPHOMAN-235 is an organo-phosphonic acid compound exhibiting excellent sequestration of metal ions at stoichiometric concentration and threshold inhibition of metal salt precipitation at sub-stoichiometric concentrations. The ability of PHOSPHOMAN-235 to de-flocculate or disperse solid particles combined with its temperature and hydrolytic stability makes it a versatile ingredient for applications requiring efficient metal ion (like Fe²/Fe³) control.

It is a nitrogenous organic polyphosphonic acid. It shows very good inhibition of the precipitation of barium sulfate (BaSO4) as well as Strontium Sulfate (SrSO4). At high alkali and high temperature (above 210 °C) environments DIETHYLENE TRIAMINE PENTA (METHYLENEPHOSPHONIC) ACID has better carbonate, sulfate, and phosphate scale and corrosion inhibition effect than other phosphonates.

Chemical Specifications & properties:

Chemical Name: Diethylenetriamine penta (Methylene phosphonic acid)

(DTPMPA / DTPMP / DETPMP / DETPMPA)

Molecular Formula: C9H28O15N3P5

CAS No.: 15827-60-8

Molecular Weight: 573

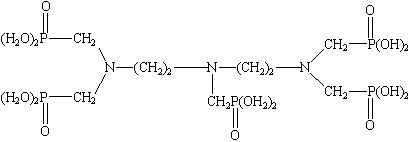

Structural Formula:

| Property | PHOSPHOMAN-235 |

|---|---|

| State | Liquid |

| pH (1% solution) | <2.0 |

| Density @ 25 °C | 1.42 ± 0.02 |

| Color | Amber aqueous solution |

| Odor | Mild acidic |

| Solid Content (min.) | 50.0 ± 2.0 % |

| Chlorides as HCl (%) | 15.0 – 17.0 |

| Iron Content (ppm) | < 10.0 |

| Solubility in Water | Soluble in all proportions |

Major Applications:

- Water Treatment Formulations / Scale Inhibitor / Antiscalant / Scale & Corrosion Inhibitor

- Soap / Detergent & Personal Care Product Additive

- Oil Field

- Paints, Pigments & Paper Industries

- Textile as Peroxide Bleach Stabilizer & Leather Auxiliary Chemicals

- I & I Cleaners

Safety and Handling: PHOSPHOMAN-235 is an acidic material. Do not take internally. In case of contact with skin, wash with plenty of water. In case of contact with eyes, flush with water and get prompt medical attention. Gloves and goggles are necessary while handling the product.

Storage: PHOSPHOMAN-235 is nonflammable, and noncombustible. It should be stored under shade. Keep the product away from direct sunlight.

Packing: PHOSPHOMAN-235 is available in 65Kg Carboy / 270Kg Polydrum / 1250Kg IBC

Tags:

DTPMP, DTPMP Chemical, DTPMP Manufacturer, Supplier of DTPMP Chemical, DTPMPA, DTPMPA Chemical, Manufacturer of DTPMP in india, DTPMP Manufacturer and supplier in India, Supplier of DTPMP Chemical Vadodara India, DTPMPA Manufacturer, Manufacturer of DTPMPA in india, Supplier of Dtpmpa Chemical, DTPMPA Manufacturer and supplier, Supplier of DTPMPA Chemical Vadodara India, DTPMPA Manufacturer and supplier in India, DTPMPA Diethylene Triamine Penta, Methylene Phosphonic Acid India, Diethylene Triamine Penta Methylene Phosphonic Acid Manufacturer and supplier, Diethylene Triamine Penta (Methylene Phosphonic) Acid, Diethylene Triamine Penta Methylene Phosphonic Acid DTPMP, Diethylene Triamine Penta (Methylene Phosphonic Acid), Diethylenetriamine Pentamethylene Phosphonic Acid manufacturers, Diethylene Triamine Penta Methylene Phosphonic Acid DTPMPA, Diethylene Triamine Penta Methylene Phosphonic Acid Manufacturer